What is the working principle of the new energy vehicle on-board charger?

Feb 14,2023 | TCcharger

1. Drive motor:

The electric motor drives the electric motor to rotate through the alternator to form a magnetoelectric force rotation torque.

2. Charging system:

The electric motor feeds the alternator through the controller, which converts the direct current into alternating current.

3. The composition of the charging system:

The electronic components of the load carried by the electric vehicle on-board charger are connected to the motor for protection. When the charger is in the charging state, the protection circuit is cut off and does not work.

The composition of the car charger:

1. Rectifier:

Using its DC charging current as an electronic rectifier, it can be charged from the input end of the DC charger and the input end of the AC power supply through the rectifier.

2. Charging system:

The charging system is an intermediate structure between the electric vehicle's on-board charger and the AC power supply. The power supply of the charger is an AC power supply, and a DC charger is usually used.

3. Composition of DC charging system:

1) The working principle of the rectifier: convert alternating current into direct current, and convert alternating current into direct current through the rectifier circuit.

2. Composition of DC charging system:

The charging system is mainly composed of a rectifier board, an inverter, a control board, a charger, and a battery pack.

A rectifier is a rectifier that converts direct current energy into alternating current. Its working principle is to use a rectifier circuit to convert alternating current into direct current.

3. Working principle of DC charger:

When the magnitude of the current changes in the counterclockwise direction, the power supplied by the AC transmission motor is transferred to a constant current through the rectifier board, and the system will continue to change. Finally, because the DC voltage is reduced to the appropriate direction of the grid, the charger will be eliminated quickly.

4. The structure of the DC charger is different, forming an ordinary DC motor:

The ordinary AC motor needs to be converted into a DC power supply through a rectifier, and the work efficiency is high, the electric energy required by the DC power can be achieved, and the conversion efficiency of some electronic devices is also reduced.

Working principle of DC charger:

When the current passes through the rectifier, it turns counterclockwise:

The DC current transmission becomes counterclockwise:

Therefore, the working principle of the DC charger is also changed. Why the speed of the DC charger has also become counterclockwise:

The conversion of AC current is a process of DC current, and the working principle of the DC charger is why a rectifier bridge is used for current conversion. The conversion efficiency of some electronic devices is fixed.

So the working principle of the DC charger is the same. When the current passes through the rectifier, it turns counterclockwise: this is the schematic diagram of the alternating current.

When the current passes through the rectifier bridge, it turns counterclockwise: so the waveform of the alternating current changes, while the working principle diagram of the direct current charger is the same.

Why use a rectifier bridge for AC power conversion? Why use a rectifier bridge for conversion? What is the working principle of the rectifier bridge? AC is converted to DC.

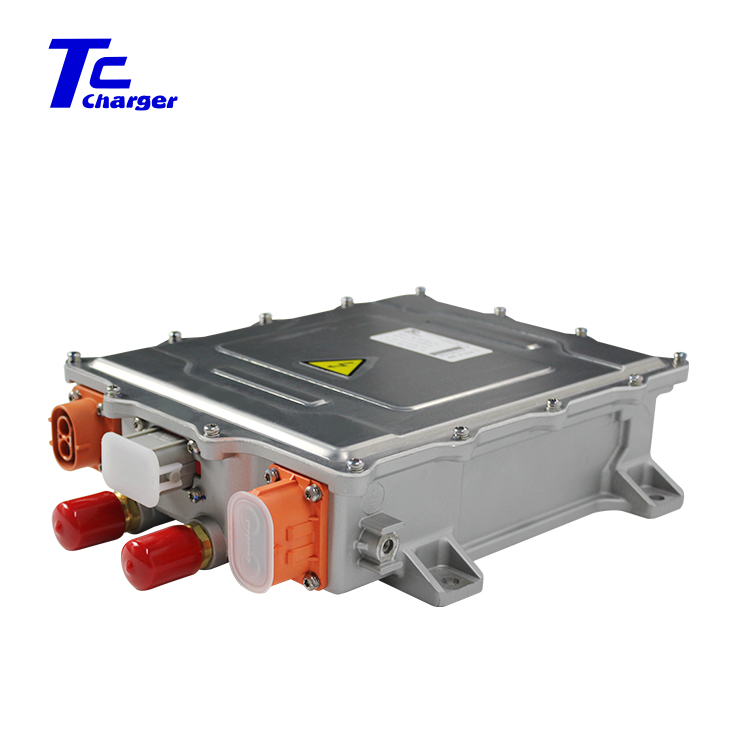

TC Charger-Manufacturer from China has been focusing on EV onboard chargers for more than 23 years. China factory covers an area of more than 2100 square meters, Standardized Serialized Large-scale Production Line, 2 patents of Technology Invention,16 Patents for Utility Models, Monthly Production Capacity with 60 K Pcs, Internationally Certified, Technology Leadership, High-Efficiency Delivery Ability, Eco-friendly EV Charger Solution.https://www.tiechengcharger.com/

24 Hours Service. Tel/WhatsApp:+86-17746808041 Email:Fancy@tiechengcharger.com