What is the onboard charger?

Nov 08,2022 | TCcharger

Most people think of electric vehicles (EV) as something new, but some of the first vehicles built in the 19th century were electric. Internal combustion engine (ICE) vehicles rapidly took over, and EVs, for the most part, were quickly forgotten. During the oil crisis in the 1970s, and in the 1990s when the California Air Resources Board (CARB) created the zero-emission vehicle (ZEV) program, EVs rose up the agenda, but failed to take hold.

This time around, the EV market is here to stay and has been growing steadily. From a charging method standpoint, EV has two primary sub-groups. The first group contains hybrid electric vehicles (HEV) and mild hybrid electric vehicle (MHEV), which charge their own battery from an ICE or regenerative braking and energy recovery. The second group contains plug-in hybrid electric vehicle (PHEV) and battery-powered electric vehicle (BEV) - the types that must “plug in” to charge. It is these vehicles that require an on board charger (OBC).

OBCs can accept either single- or three-phase mains and deliver as much as 22kW of power for the fastest possible charging. As all batteries require DC power to charge, the core function of the OBC is to rectify the mains input and convert it to a suitable charging voltage for the battery – which may be 400V or, increasingly, 800V.

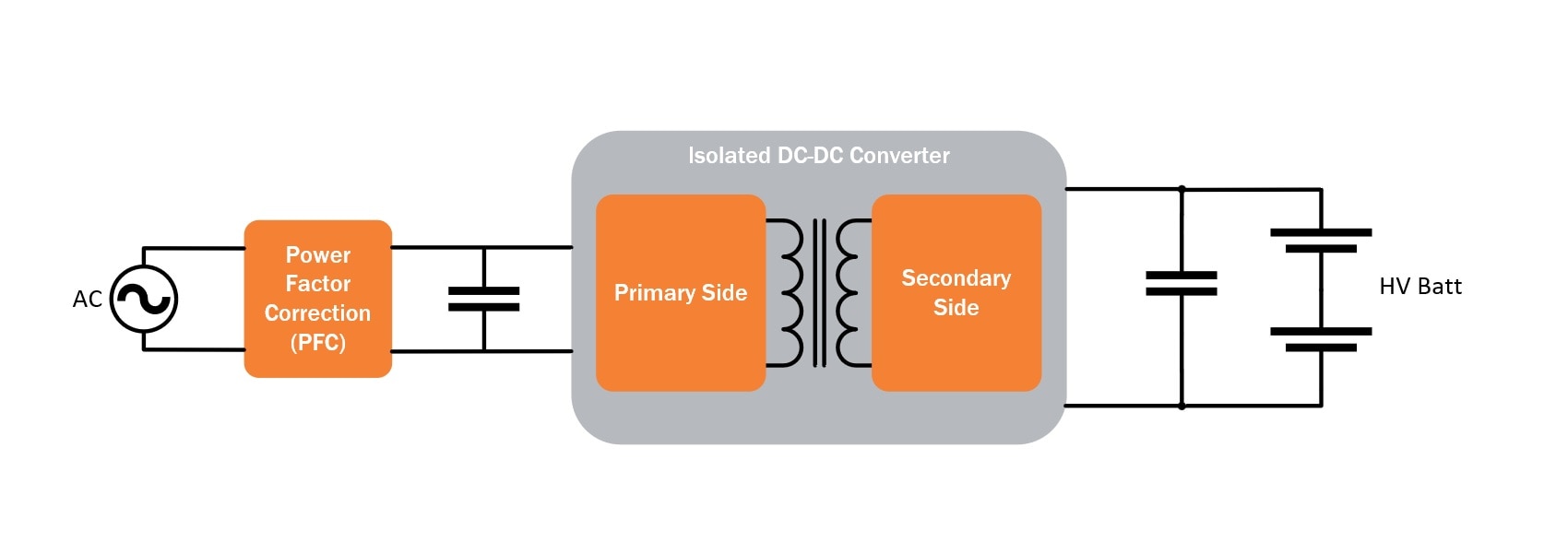

OBCs have two principal stages. First, the Power Factor Correction (PFC) stage that maintains the phase relationship between input current and voltage and minimizes total harmonic distortion (THD) in the line/grid current. This helps to reduce any wasteful reactive power and improve overall efficiency.

The second stage is the DC-DC converter, which takes the DC output from the PFC stage and converts it to the level needed for charging the battery. The converter output voltage and current change over time, based upon the overall state-of-health and state-of-charge of the battery.

Some OBCs are being designed to provide bidirectional capability, allowing both grid-to-vehicle and vehicle-to-grid power transfer. This will allow energy companies and customers to tap into the huge amount of stored power in EVs, providing additional energy reserves to cope with peaks in demand. Owners will benefit as they sell the power to the grid at peak times (therefore a higher price) and replenish their vehicle during off-peak times, providing a small income for the use of their stored energy by utility companies.

Most unidirectional OBCs use an LLC or Phase Shifted Full Bridge (PSFB) topology. For bidirectional designs, CLLC or dual active bridge (DAB) are common and growing in popularity. Silicon carbide (SiC) MOSFETs are increasingly used to benefit from lower switching losses, faster switching speeds and higher operating temperatures.

The secondary side rectification for a unidirectional OBC can be passive (using diodes) or synchronous which uses power switches for better efficiency. In a bidirectional OBC, secondary rectification will need to be a full bridge that supports CLLC, or the second half of a dual active bridge. In all cases, the use of silicon carbide devices (diodes and switches) will increase efficiency and deliver robustness. However, in some cost optimized OBC designs super-junction MOSFETs may still be used, depending upon the power levels, voltages and acceptable efficiencies.

The huge difference in battery capacities within EVs is driving a need for scalability and flexibility in OBC design. For example, the battery in a light passenger vehicle typically ranges from 30kWh to just over 100kWh, while in larger vehicles such as SUVs this figure may rise to 150kWh. The trend is for the capacity of battery packs to increase, to extend the range of EVs between charges. Some passenger vehicles entering the market have battery capacities approaching 200kWh, and larger batteries will migrate to 800V to expedite the charging process.

Depending upon the OBC topology selected, multiple types of semiconductor devices will be required. TC Charger provides solutions for automotive OBC power stages from 3.3kW to 22kW, and battery voltages up to 800V. The portfolio includes SiC MOSFETs, hybrid IGBTs with co-packaged SiC diodes, Super-Junction MOSFETs, automotive power modules (APM), SiC diodes, gate drivers, regulated power, and in-vehicle networking solutions.

Implementing TC Charger technology enables customers to deliver flexible OBC and infrastructure charging solutions, for a wide range of EV applications.